Packaging and kitting errors slow down production, trigger rework, and create hidden supply chain inefficiencies. Many of these issues stem from manual processes that are unable to scale or ensure precision under pressure. Manufacturers aiming to remove these obstacles are turning to machine vision AI for packaging and kitting inspection as a long-term solution.

Unlike traditional systems, machine vision platforms powered by AI don’t just check presence or position. They analyze, learn, and adapt to product variations in real time. This level of flexibility is critical when production environments deal with multiple SKUs, tight lead times, and frequent configuration changes.

Why Manual Packaging Validation Is No Longer Sustainable

Manual inspection works at low volumebut it breaks at scale. Operators miss subtle misplacements, overlook missing items, or misidentify parts when workloads increase. These mistakes lead to:

- Incorrect shipments reaching customers

- Assembly delays due to missing components

- Compliance issues in regulated industries

More importantly, rework in kitting lines wastes labor, impacts on-time delivery, and drives up cost per unit. As discussed earlier, these are the exact points where AI-based systems outperform static checks.

Automation Without Rigidity

Most manufacturers hesitate to automate kitting validation because of the perceived rigidity of fixed systems. However, modern platforms built with machine learning in packaging adapt to dynamic environments.

When a new configuration enters the line, the AI model recognizes changes in part orientation, count, and label placement. That allows for AI-powered kitting validation without needing to retrain the entire system from scratch.

This flexibility is especially useful when working with customized kits or products packed on demand.

Visual Inspection at Scale Without Compromise

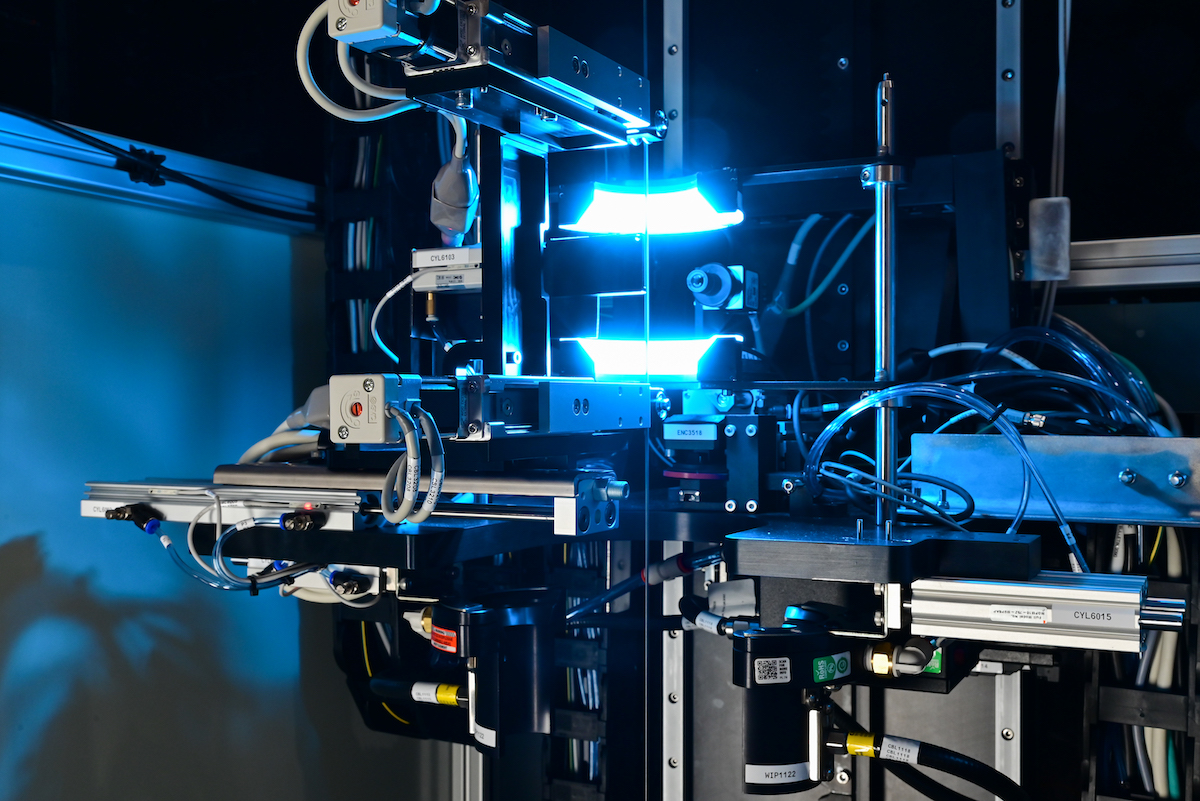

One of the biggest advantages of machine vision AI for packaging and kitting inspection is the balance between speed and accuracy. Cameras capture images from multiple angles while AI analyzes each frame within milliseconds.

This approach supports:

- Verification of item completeness

- Label accuracy checks

- Real-time feedback to operators

As mentioned previously, manual systems often flag issues too late. In contrast, AI-based inspection offers early detection that minimizes waste and allows operators to intervene before errors compound.

Preventing Bottlenecks Through Integrated Intelligence

Errors in packaging or kitting often cascade through the supply chain. A mislabeled part delays final assembly. A missing screw halts installation. These are not isolated issuesthey are supply chain liabilities.

By integrating visual inspection for packaging directly into the line, companies reduce dependencies on downstream checks. When paired with supply chain automation, this creates a self-correcting system that improves throughput and accuracy at the same time.

Where Does This Matter Most?

Facilities handling subscription kits, spare part bundling, or serialized products see the greatest ROI. In these settings, the error-free packaging process isn’t just about precisionit’s about traceability and customer satisfaction.

Using automated packaging inspection, these businesses ensure that each outbound unit meets spec, every time. Mistakes don’t just cost moneythey erode trust. AI systems ensure that inspection happens consistently, even during peak demand or labor shortages.

What to Expect Moving Forward

As more manufacturers adopt machine learning in packaging, the value goes beyond quality control. Inspection data becomes part of a larger feedback loopused to optimize upstream processes, retrain models, and improve accuracy over time.

This data-driven approach to packaging and kitting supports continuous improvement without increasing headcount or cycle time.

Final Thought

Building on all the points above, automation is no longer just about reducing headcount. It’s about eliminating repeatable friction in fast-moving supply chains. And in that context, machine vision AI for packaging and kitting inspection is not an optional upgrade. It’s a strategic priority.